Successful product development goes beyond delivering quality parts on time. Our tedious attention-to-detail sets us apart.

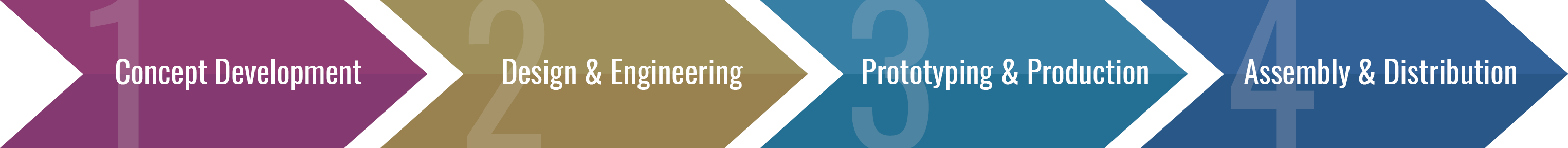

From innovative mold design to prototyping to packout and distribution – we add value from start to finish!

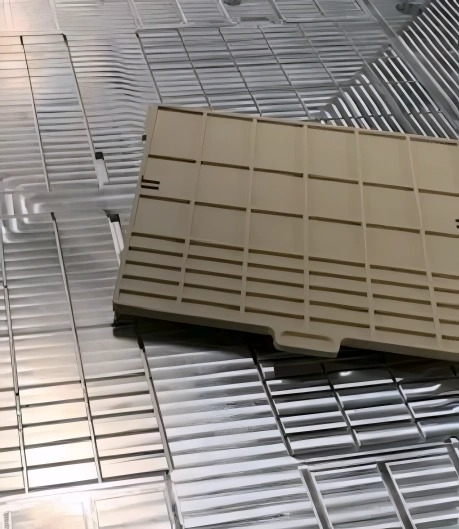

Thoroughbred’s domestic in-house tool facility provides our customers low-cost, quick turn injection molds unmatched in the industry.

We regularly provide first shots on multi-mold programs in 6 weeks or less

Our proven reputation for customer satisfaction through quality, speed and on-time delivery, continues to propel our growth in the demanding retail merchandising display market.

Thoroughbred Plastics provides injection molding services ranging from in-house mold construction through final assembly/fulfillment.

Our designers and engineers use multiple software platforms to streamline communication during the development process.

Our customer’s molds are regularly recycled creating a partnership to hold tooling costs low and improving overall lead times.

Thoroughbred Plastics provides complete assembly and pack out services for production quantities ranging from 100 to 1 million.

We have the space and personnel to manage large product launches.

Our logistics team will coordinate the timely shipment of orders through customer-preferred carriers and ensure all the shipping documentation and barcoding are seamless to your customers.

Corporate Office

Rockford, IL – (815) 985-5116

Click Here to Email Us.

Customer Service Support

Austin Leitzinger – (815) 298-0065

Technical/Engineering Support

Tom Gustafson – (815) 985-5116